Custom Metal Injection Molding Suppliers

Product Introduction

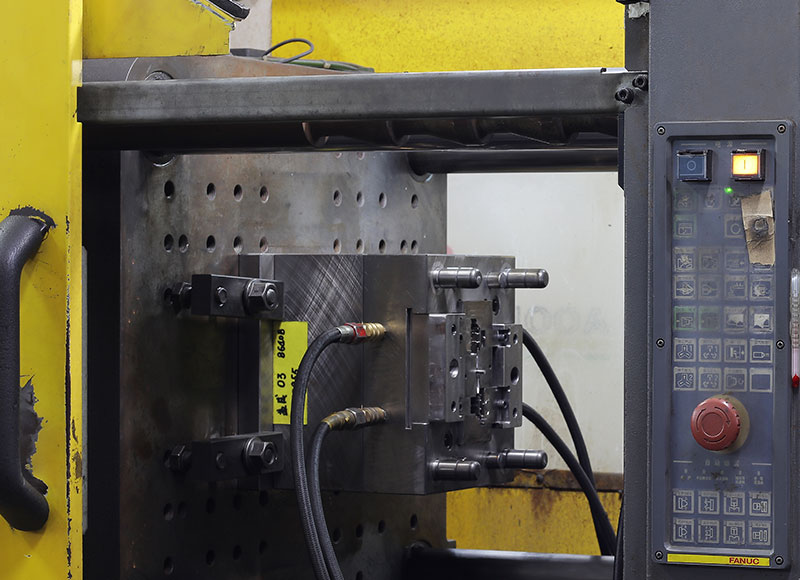

Jinholly metal injection molding company employs high-quality injection molding equipment and various special injection forming molds to greatly improve production efficiency and stabilize quality, and continuously perfect and study various MIM machining conditions to enhance our technology and capabilities.

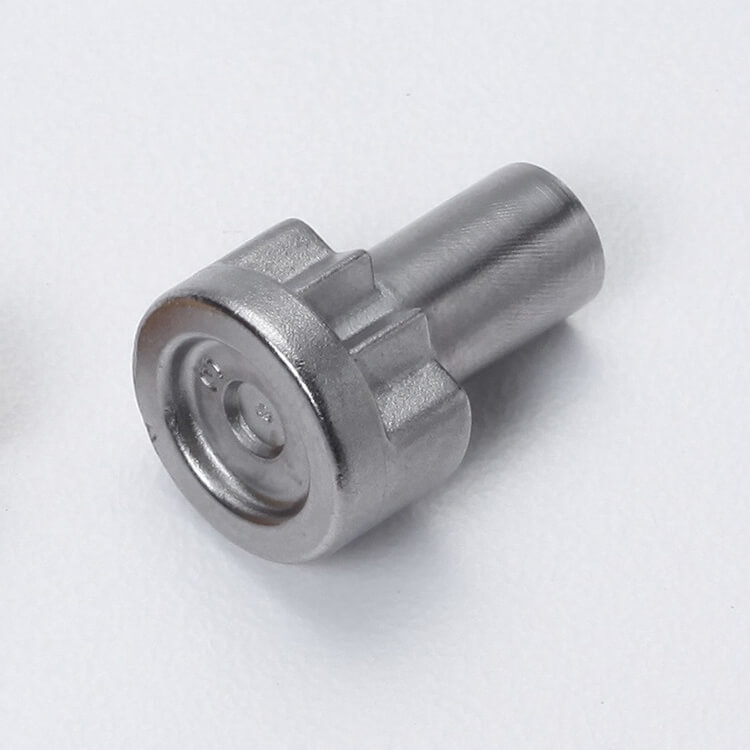

We have CNC lathes and CNC milling machines to process the materials after forming and sintering, and to control the stable dimensions based on the needs of the clients. We can conduct further precision machining in shaping, drilling, reaming, tapping, grinding, and turning, etc.

As a leading metal injection molding company with more than 20 years of professional injection molding manufacturing technology and processing experience, we can help clients solve any problems related to manufacturing.

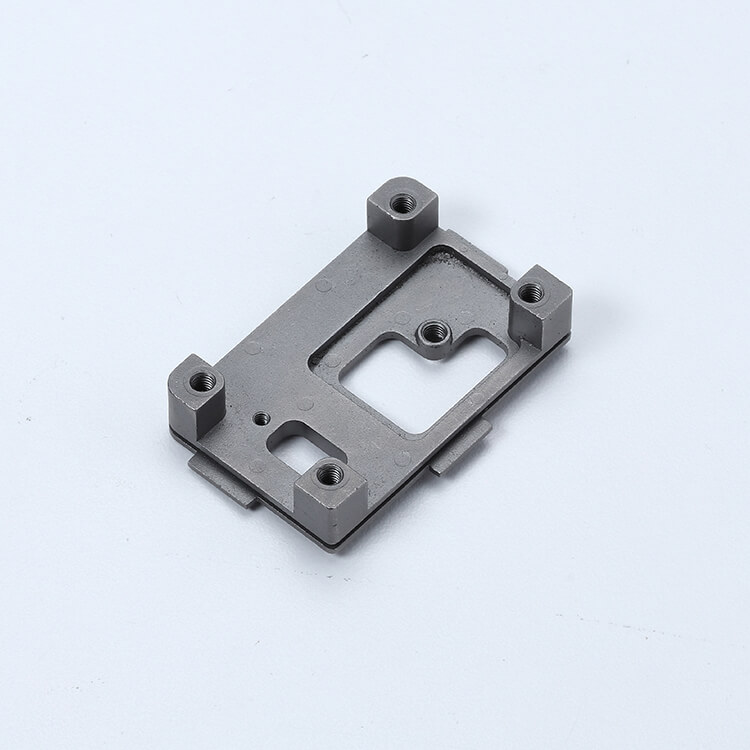

Metal injection molding is suitable for manufacturing products with small and complex shapes, high dimensional precision, toughness, high density, and good surface roughness, thus eliminating the need for precision machining and reducing material consumption.

Our products can be widely used in 3C electronic parts, medical devices, auto parts, motorcycle parts, bicycle gears, hand tool parts, pneumatic tools, power tools, sewing machine parts, locks, lock cores, office machine parts, and drive shafts, etc.

Metal Injection Molding Supplier with Abundant Experiences

Advantages of metal injection molding:

- The manufacturing method uses mold forming, which is suitable for mass production.

- The material is of strong mechanical properties, high toughness, and high diversity.

- Our expertise on high shape complexity can reduce the processing procedure and costs.

Expert Metal Injection Molding Services by Jinholly

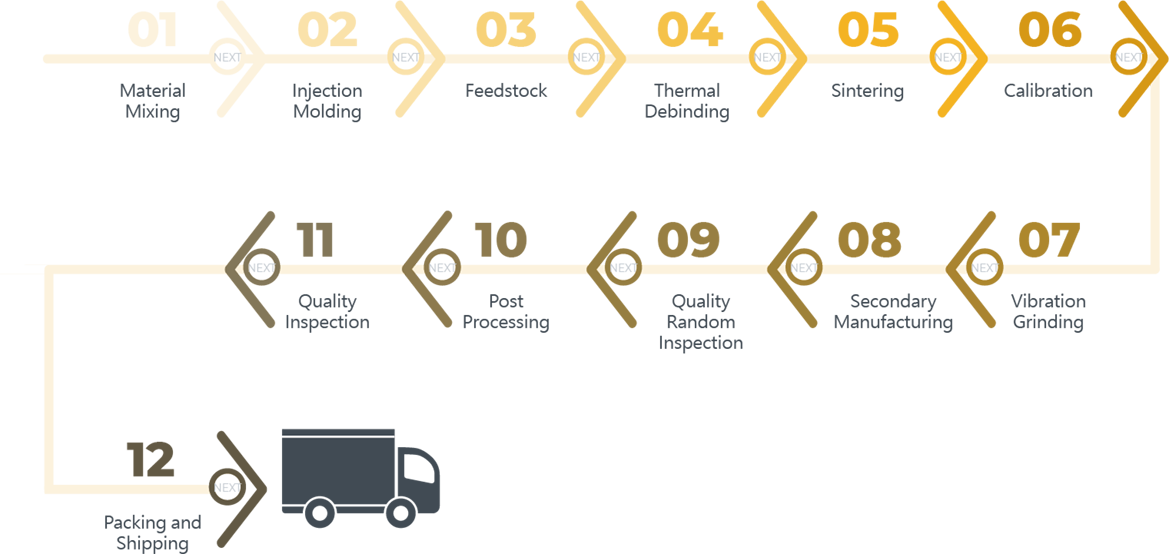

Metal injection molding (MIM) demands deep technical expertise due to the complexities of factors such as mold size precision, sintering stability, and potential shape deformations during production. A thorough evaluation process is essential to ensure successful product development and manufacturing outcomes.

With over 20 years of proven experience in the field, Jinholly is a trusted leader in MIM solutions. Our team leverages cutting-edge technology and specialized knowledge to address even the most challenging material tolerances and dimensional requirements. By combining state-of-the-art manufacturing equipment with rigorous quality control, we consistently deliver products that meet the highest industry standards.

At Jinholly, we are dedicated to excellence in every aspect of metal injection molding, ensuring our clients receive unparalleled service and superior-quality results for their most demanding applications. Contact us today to discuss your project needs!

Sincerely welcome relevant buyers from all over the world to visit and cooperate.

-

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products -

Customized Products

Customized Products

OEM / ODM Solution

Select appropriate processing methods for clients to help them reduce costs, achieve high efficiency, and high-quality service.