Processing Services

Jinholly - Your Partner for Metal Machining Services

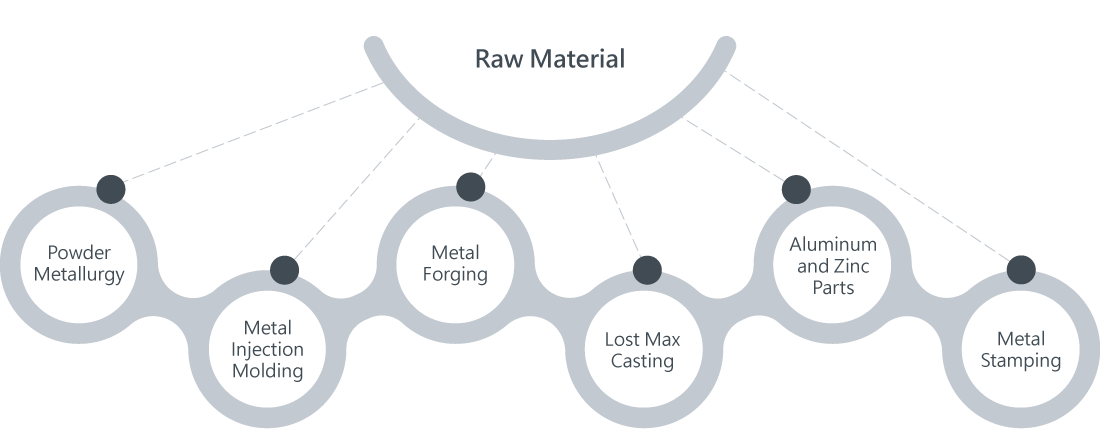

As an integrated manufacturer and exporter, Jinholly Co., Ltd. is dedicated to providing high-quality metal machining services to meet the diverse needs of our clients. Our state-of-the-art factory in Taiwan specializes in various metal processing services, including metal stamping, lost wax casting, and more. With a team of skilled professionals and advanced equipment, we ensure the timely delivery of first-class products that meet the highest standards.

Global OEM and Custom Metal Shaping Services

Jinholly has been at the forefront of hardware manufacturing, offering global OEM and custom metal shaping services to cater to the evolving needs of our clients. Our expertise in optimizing the manufacturing process enables us to shorten production cycles and reduce transportation costs. From raw materials to finished or semi-finished products, we tailor our services to meet the specific requirements of our clients.

In addition to our core metal machining services, we offer a range of additional services, including surface treatment, heat treatment, and other processing services. Our flexibility in meeting client needs ensures that we can accommodate diverse requirements and deliver customized solutions that exceed expectations.

OEM / ODM Solution

Select appropriate processing methods for clients to help them reduce costs, achieve high efficiency, and high-quality service.